-

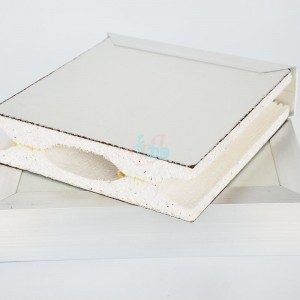

Machine-made PU Sandwich Panel

Polyurethane rigid foam is isocyanate and polyether as the main raw materials, the polyurethane foaming agent is evenly sprayed on the color steel plate surface layer, is the foaming agent between the color steel plate foam molding into a three-layer disposable polyurethane composite sandwich plate. This new light building material is the perfect combination of color steel plate and polyurethane, and is widely used in wall buildings with thermal insulation requirements such as clean rooms and cold storage.

-

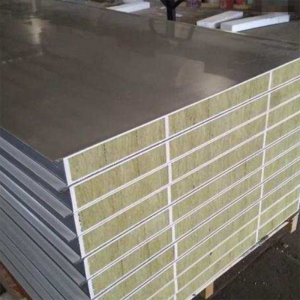

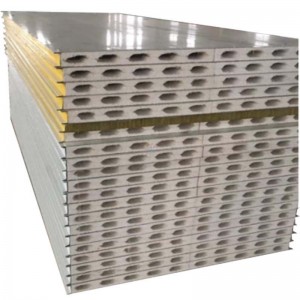

Machine-made Rock Wool&Glass Magnesium Sandwich Panel

High-quality color coated steel plate is used as the surface layer, galvanized steel strip is used as the edge sealing room and reinforcing ribs, moisture-proof glass magnesium plate is used as the core layer, rock wool is used as the inner core layer, which is manufactured by pressurizing, heating and other processes. It has good sealing performance and high fire protection level.

-

Machine-made MGO Sandwich Panel

The raw material of magnesium oxysulfide is non-combustible A1 grade, and the color steel plate of magnesium oxysulfide sandwich is a color steel sandwich plate made of magnesium oxysulfide slats or magnesium oxysulfide hollow plate composite color coated steel plate.

-

Machine-made EPS Sanwich Panel

Polystyrene foam sandwich panel is based on polystyrene resin as the main body, increase flame retardants, fireproof insulation adhesive on polystyrene foam panel for fireproof coating modification, so that fireproof insulation adhesive penetrates into the polystyrene foam panel to prepare polystyrene fireproof insulation panel.

-

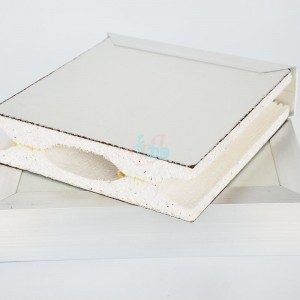

Machine-made Glass Magnesium Sandwich Panel

Glass-magnesium sandwich panel is made of magnesium oxide, magnesium sulfate, and water ternary system through configuration and modifier. It is a magnesium-based cementitious material with stable performance. It is reinforced by medium-alkaline glass fiber mesh. Material, a new type of non-combustible decorative material compounded with lightweight materials as fillers. It is processed by special production technology and has the characteristics of fireproof, waterproof, odorless, non-toxic, non-freezing, non-corrosion, non-cracking, unchanged, non-combustible, high-strength and light-weight, convenient for construction and long service life.

-

Machine_made Magnesium Oxysulfide Sandwich Panel

The raw material of magnesium oxysulfide is non-combustible A2 grade, and the magnesium oxysulfide sandwich panel is steel sandwich plate made of magnesium oxysulfide slats or magnesium oxysulfide hollow plate composite color coated steel plate.

-

Machine-made Paper Honeycomb Sandwich Panel

Paper honeycomb sandwich panel is a new type of high-tech building material, which has gradually replaced traditional core materials such as rock wool, EPS and PU. The paper honeycomb sandwich panel has better performance than the traditional core material sandwich panels: it has higher flame retardancy, lighter self-weight, stronger load-bearing capacity, better sound insulation effect, and stronger environmental protection performance. Paper honeycomb purification panels have been widely used in clean building industries such as electronic, biological, food, pharmaceutical, hospitals, military, etc., and are products of modern buildings.

-

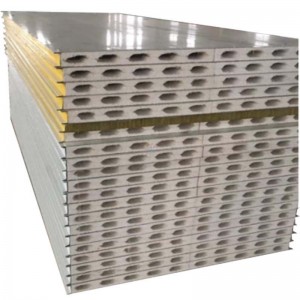

Machine-made PU Sandwich Panel

Polyurethane sandwich panel is isocyanate and polyether as the main raw materials, the polyurethane foaming agent is evenly sprayed on the steel plate surface layer, is the foaming agent between the color steel plate foam molding into three layers of disposable polyurethane composite sandwich panel. This new light building material is a perfect combination of painted steel plate and polyurethane, and is widely used in wall buildings with thermal insulation requirements such as clean rooms and cold storage.

-

Machine-made Slincon Rock Sandwich Panel

The silica rock sandwich panel is mainly made of polystyrene, which is originally a good low thermal conductivity raw material. It is then extruded to form a tight structure, which effectively prevents heat conduction and has high resistance. , the characteristics of low linear expansion rate. The difference from rock wool board is mainly in the temperature resistance, thermal conductivity and temperature resistance limit of the board. The use of silica purification board can not only meet the requirements of thermal insulation and energy saving, but also prevent fire.

-

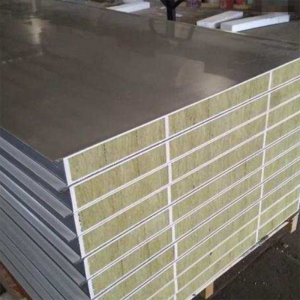

Machine-made Rock Wool Sandwich Panel

Using medium and high density rock wool as the core material, galvanized or color coated board as the surface layer and high strength adhesive, through high-speed continuous automatic molding machine heating, pressure composite, after trimming, slotting, cutting the new generation of architectural decoration board, with thermal insulation, convenient installation characteristics. It is a new type of fireproof plate with the strongest fireproof performance in the same kind (sandwich plate series).